“When I decided to launch the project of Magnifica I knew that in order to make an excellent quality product I needed to combine the tradition of the old pot still cachaças with the nature of the Rio de Janeiro mountains. The ancient know-how would allow me to perfectly exploit a sugarcane which had grown in the best possible climate.”

João Luiz de Faria

The production process follows these steps:

The sugar cane comes from our own estate

All sugarcane used for the production of Magnífica cachaça comes from our own estate. The Fazenda do Anil is located at roughly 70 miles from Rio de Janeiro city, at an altitude of 800 meters, in an unspoilt environment with the purest air and water.

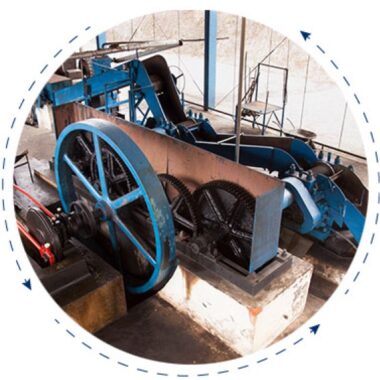

Fresh sugarcane juice

The sugarcane is harvested manually and is pressed while still fresh. Our press is actioned by a centenary steam engine which uses the leftovers from the juice extraction to create its own energy source. This process is 100% sustainable.

The fresh sugarcane juice is then sent to the fermentation vats.

100% natural fermentation

The fresh sugarcane juice is fermented in a natural process without any additives. It is during this phase that the aromatic components of cachaça are formed thanks to the combined action of the natural yeast and local micro organisms.

“Alegria” copper pot still, unique in Brazil

Magnifica cachaça is distilled in a triple copper pot still known as “Alegria”, one of the very few of this type still functioning in Brazil.

His special pot still allows the extraction of the best aromas and flavors during distillation while preserving the purity of the cachaça.

Ageing in noble woods

In order to age its various products, Magnifica uses vats of ipê, one of the noblest woods of Brazil, and American oak barrels.

The aging warehouse is located in the estate, thus benefiting from its cool mountain climate

Sustainability

Magnifica production is based on sustainable processes and on minimizing its impact on nature. Our main energy source is steam, generated from burning the dry leftovers of the sugarcane pressing. CO2 liberated through this process is recaptured through the growth of our own plantation, leaving a virtually neutral carbon footprint.

The liquid leftovers from distillation are used as fertilizers, thus returning to the earth the organic material from the sugar cane.

The trees from our estate are preserved as well as the water sources which are of the purest quality.

Magnífica de Faria

Visit the Estate

The Fazenda do Anil, where our distillery is located, is open to visits with prior reservation. The program can include the visit to the pot still and to the aging warehouse, with a cachaça tasting or a more thorough program including lunch at the estate.